Is your business in need of efficient and reliable packaging machinery for complete automation of your packaging systems? Consider getting strappers, stretch wrappers, shrink wrappers, tape machines, and much more from some of the top brands in the industry. Whatever your packaging specifications, FastPak has the tools and equipment to optimize your packing and shipping process.

Before you make a purchase, it is important to understand your product options – especially when it comes to shrink wrappers and stretch wrappers.

Shrink Wrappers vs. Stretch Wrappers

At first glance, both of these products look similar. However, when you talk with stretch film suppliers or other shipping and receiving professionals, you’ll find many differences between them. In many ways, they act in the same way as cling wrap in your kitchen to wrap up leftovers, except they’re controlled by temperature.

So, what is the most notable distinction between the two? Stretch wrap stretches around products. It has a degree of elasticity that lets you pull it taut around your shipments and holds everything tightly together. In contrast, shrink wrap goes loosely around your products or shipments. Then, to tighten it, you need to apply heat, which can often be done with a blow dryer.

Shrink Wrappers

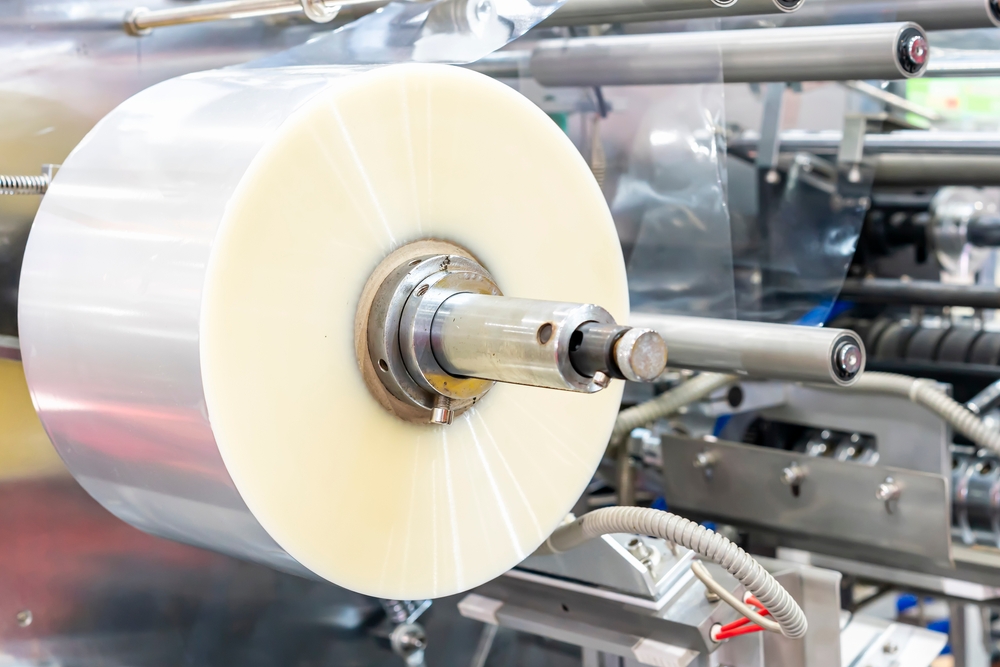

Shrink wrappers are a plastic film used to package products from toys and fresh produce to frozen foods. By applying heat to the plastic, it shrinks to fit the container, providing a secure and protective seal.

In addition to many other packaging films available at FastPak Systems, you’ll find reliable shrink film products that can give your systems precisely what they need to maintain efficiency and cost-effectiveness.

Shrink wrapping equipment is available in various product sizes and both automatic and semi-automatic formats. At FastPak, we can help you find the most suitable shrink wrap machines tailored to your operation’s unique needs.

Advantages & Uses

With shrink wrappers, you have the power to efficiently resolve your cardboard shortage issues with a creative distribution packaging solution. Discover more about its benefits below:

- Extends Shelf Life – Shrink film (utilizing modified atmosphere packaging) can extend fresh produce’s shelf life by preserving and preventing spoilage.

- Customizable – Since shrink wrappers automatically conform to the shape of their wrapping, it’s entirely customizable and reduces dimensional weight shipping costs.

- Simple, Complete Process – Shrink wrappers complete the entire packaging process, from wrapping to labeling.

- Less Labor – Fully automatic shrink wrappers demand less labor to operate the machinery.

- Reduce Waste and Costs – Transitioning to a shrink wrap alternative compared to cardboard box packaging significantly reduces waste and the cost of packaging.

- Technological Advancement – Technology continues to advance. However, with the advancements in shrink packaging equipment, only some products need a secondary cardboard box. This application will work for any product that doesn’t require additional protective packaging materials.

Additionally, shrink machines are one of the many packaging machines you’ll find at FastPak Systems. You can use our shrink machines for packaging various products using different shrink films. We offer several types of shrink machines depending on your application’s specific needs, which can help lower film expenses and maximize efficiency in your production lines.

Stretch Wrappers

Stretch wrappers provide exceptional product protection and a safer environment for your workers. It is wholly semi-automatic and involves a thin, stretchable plastic film made from polyethylene to secure cased goods onto a pallet tightly. Tension is applied to the stretch film wrapped around the pallet, allowing it to extend by up to 300 percent and hold it in place.

With our stretch film, you can get some of the best results from your operations while lowering costs on materials. Suppose you need a reliable stretch wrapper to use in conjunction with our stretch film. In that case, we carry semi-automatic and automatic models to reduce film costs and increase load stability.

Semi-automatic wrappers are helpful in many low-output applications, while our fully automatic machines can wrap up to 100 loads an hour or more. We also offer special application machines that bundle products and provide sufficient packaging for odd-shaped and longer products. You can learn more about our stretch wrapping equipment here.

Advantages & Uses

Stretch wrappers encompass many benefits and applications, including the following:

- Reduced Damages – Shipped goods are subject to events that can cause damage to packages. However, stretch film and its equipment reduce such hazards due to its ability to hold loads tightly.

- Secure Protection – Stretch film protects casings from dirt, dust, and moisture.

- Sustainability – Many stretch films are recyclable and better for the environment.

- Budget-Friendly – Stretch film and stretch wrappers are a cost-effective alternative to other packaging methods like strapping, saving you both time and money.

Get Quality Shrink Wrappers and Stretch Wrappers with FastPak

FastPak is proud of its ability to maintain quality for each machine and product we carry. We provide the best shrink machine solution to meet your application specifications. Working together, we’ll help you find the perfect machine to integrate into your packaging lines.

Call 770-423-0795 or send an email to info@fastpaksystems.com for your order today.