Today’s distribution and manufacturing landscape is extremely modernized. With advanced innovative technology such as shrink and stretch wrapping, there seems to be no limit to an item that can be shipped safely. Very fragile, heavy, bulk, or temperature-sensitive goods can be wrapped and shipped for secure, timely arrival. Find out exactly what stretch wrapping is and how your business’s shipped products will benefit from it.

What is Stretch Wrapping?

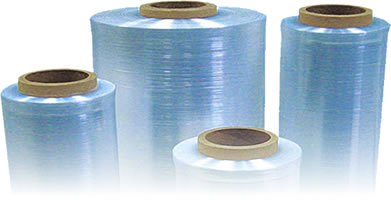

Stretch wrap, also known as pallet wrap or stretch film, is sometimes incorrectly referred to as shrink film. It is a thin elastic film that is expertly stretched and wrapped around items. Stretch film creates a snug protective cover that holds items together to prevent shifting, scratches, dents, leaks, and other damage during transit and handling. It is a versatile and flexible packaging material to secure goods during the shipping (transportation) process.

Difference Between Stretch Wrapping and Shrink Wrapping

A clear distinction exists between stretch wrap and shrink wrap.

| Stretch Wrapping/Pallet Wrapping | Shrink Wrapping |

| · Tightly encases around a product

· Stretchable plastic (high elasticity) · Does not shrink with heat applied · Commonly used to wrap and protect pallets of products · Does not conform to an item’s shape but still secures goods and creates a tamper-resistant seal |

· Loosely encases around a product

· Not stretchable (no elasticity) · Shrinks tight once heat is applied · Commonly used to wrap and protect one product such as food or bottles · Conforms to the item’s shape to create a tamper-resistant seal |

What is Stretch Wrap Made Of?

Stretch wrap is commonly made from linear low-density polyethylene (LLDPE) resin, derived from petroleum and natural gas, and molded into durable, stretchable rolls. LLDPE is a plastic polymer with a higher impact strength, tensile strength, and puncture strength than low-density polyethylene (LDPE), a similar thermal plastic.

How is Stretch Wrapping Useful for My Business?

Cost Savings: Stretch wrapping is a cost-effective solution that minimizes the need for excessive packaging materials such as extra Styrofoam, bubble wrap, and more. Reduce labor and material costs for savings over time.

Elevated Protection: Stretch film wraps securely around any item to create a protective stable cocoon for product integrity.

Enhanced Brand Perception: Stretch wrap is clear, allowing graphics to show through the film.

Tamper Resistance: A product that is securely wrapped is more resistant to tampering, allowing for increased customer trust and fewer goods stolen.

Improved Efficiency: Easily automate the packaging process for faster order fulfillment and reduced shipping times.

Enhanced Product Protection: Securely stabilize goods to reduce the risk of damage during the shipping process and storage.

Versatility: Stretch wrap can be used for a wide range of products, regardless of size, shape, weight, or quantity.

Environmental Impact: Using less packaging material contributes to sustainability and less waste. Used stretch film is recyclable. Most film manufacturers accept used film for reprocessing.

How Can Stretch Wrapping Benefit My Products?

The primary purpose of stretch wrapping is to provide stability and protection to products as they move through the supply chain. By securely holding items together, stretch wrap prevents shifting, tumbling, or toppling during transit. Additionally, stretch wrap helps to guard against moisture, dust, and other environmental factors that could compromise the quality of the goods you sell.

It’s good to ask your stretch wrap supplier specific questions about how it will wrap your products regarding dimensions, weight, or temperature. This is particularly important for fragile, irregularly shaped items, and temperature-sensitive goods that might be susceptible to damage.

Mechanics of a Stretch Wrap Machine

A typical stretch wrap machine consists of a turntable or rotating arm that holds the roll of stretch film.

- Products are placed on the turntable or beneath the rotating arm.

- As the turntable rotates or the arm moves around the product, the stretch film is unwound and stretched, forming a tight wrap around the item.

- The wrapped item is easily checked for security before shipping.

Count on Fastpak for Your Business’ Stretch Wrapping Needs

When seeking to optimize your business’s packaging and shipping processes, ensuring the safety and integrity of your products is paramount. Unlock the benefits of stretch wrapping with Fastpak – your trusted Stretch Wrap Supplier.

Contact Fastpak today to explore the potential of stretch wrapping for your business.