Foam cushions, also known as packaging foam, cushioning foam, and foam inserts, have emerged as a leading solution to ensure the safety of products during transit. Are you a business owner seeking to enhance your packaging strategy for goods shipped to clients and customers? Read on to learn the convenience of purchasing foam cushions in bulk for your small business (or large business) needs.

Why Choose Foam Cushioning for Packaging?

- Exceptional cushioning properties and versatility make it an essential choice for packaging items of various sizes and fragility.

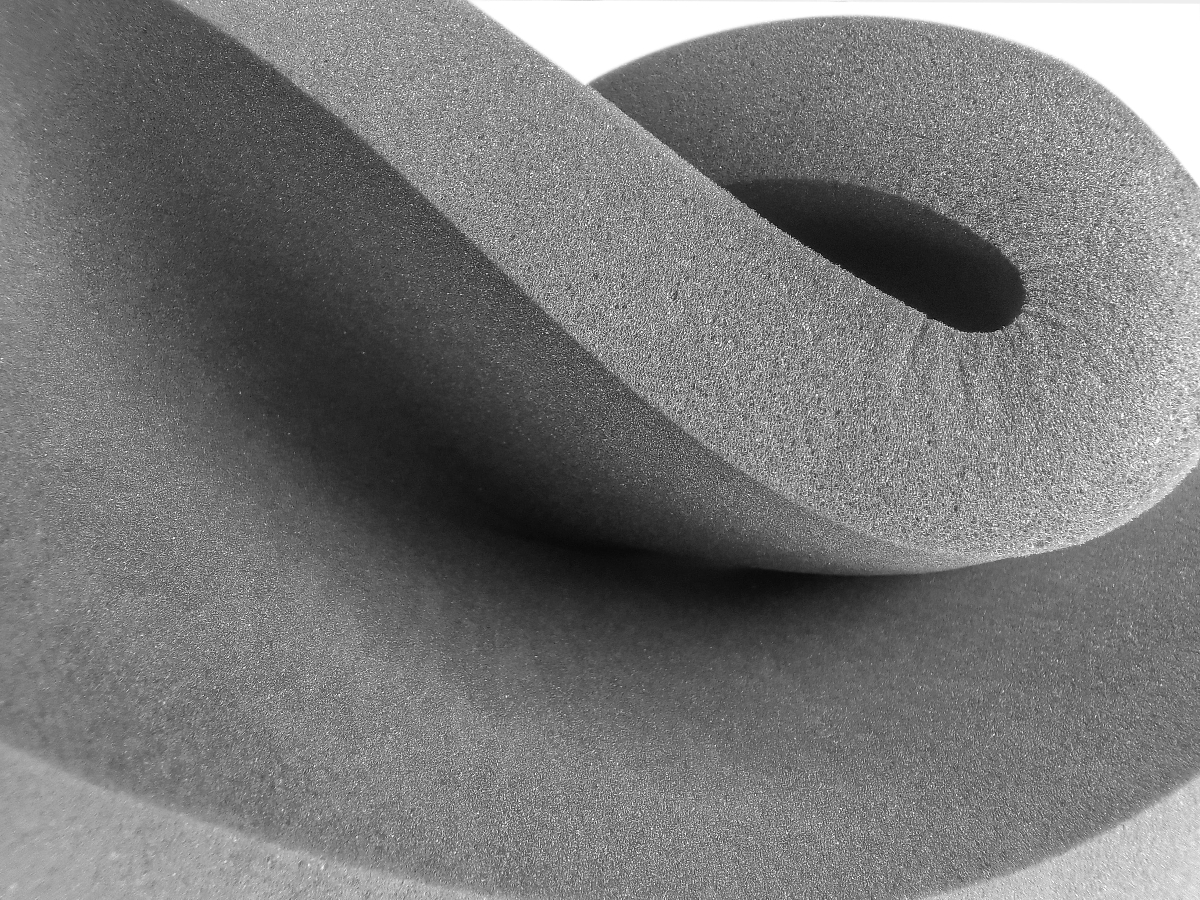

- Cushioning foam easily conforms to the shape of any item to safeguard a snug fit; it minimizes movement during transit and reduces the risk of damage.

- Foam inserts provide a cushioned, shock-absorbed barrier for fragile electronics, glassware, intricate components, and more, which avoids impact-related damage.

- Foam sheets and rolls are versatile and can be easily cut and shaped to provide custom protection for products of all sizes.

- Foam inserts are precision-cut to support individual items, ensuring they remain securely in place during shipment.

What are Foam Cushions Made From?

- Polyurethane foam is the most common for heavy objects because of its durability and resilience to prevent shifting during transit.

- Expanded polyethylene foam (EPE foam) is the most common for delicate items because it’s lightweight with excellent shock-absorbing capabilities. Polyethylene foam also has substantial memory, allowing it to absorb multiple impacts without compromising the material.

- Expanded polystyrene (EPS) foam is the most common for products that require temperature control because of its insulation properties.

Varieties and Types of Packaging Foam

Packaging foam can be found in different shapes and textures to cater to different weights, dimensions, textures, and fragility.

Egg Crate Foam

This is a highly breathable foam with shock and sound absorption shaped like an egg carton.

Antistatic Foam

This protects goods from static discharge so there is no friction during transit.

Foam End Caps

These are specifically placed on the corners or ends of products to be shipped to avoid scratches, dents, and other damage to pointy angles.

Die-cut Foam Cushions

These are for products with intricate designs; they are meticulously crafted to fit the contours of the item, leaving no room for movement.

Foam-in-Place

Foam-in-place or foam-in-bag allows the user to create custom foam packaging on demand to protect high-value fragile items. This is the most versatile type of foam cushioning as it begins in a liquid form and expands to fill the space between the container and the object. Foam-in-place can also be used to create custom molds for more uniform presentation and protection.

Foam Cushions vs. Bubble Wrap

Unlike paper or bubble wrap, foam cushions provide consistent and reliable protection across a wide range of items.

| Advantage | Foam Cushions | Bubble Wrap |

| Do not pop | YES | NO |

| Do not lose their protective properties over time | YES | NO |

| Maintain cushioning for the entire shipping process | YES | NO |

| More environmentally friendly (can be recycled or reused) | YES | NO |

| Can withstand repeated impact | YES | NO |

How Foam Cushions are Used in Packaging

- Foam cushions are placed at the bottom of the shipping container.

- Next, an item is positioned on top.

- Additional foam is placed on the side and ends for a secure fit.

- A foam cushion is placed on top to prevent any vertical movement.

Buying Foam Cushions in Bulk for Your Business

Cushioning foam is easy to use and adapt to a variety of packaging circumstances. As a shipper (we want the big ones too.), you can reap substantial benefits by purchasing foam cushions in bulk. Buying in larger quantities often translates to cost savings per unit, allowing you to allocate your budget more efficiently. Many top packaging suppliers offer a range of foam cushion options to cater to different product sizes and packaging requirements. By stocking up on foam cushions, you ensure a consistent supply, streamline your packaging process, and enhance the overall professionalism of your product presentation.

Foam cushions have revolutionized protection and security. With a diverse range of foam types and cushioning options, foam cushions are well-equipped to accommodate various packaging needs. When compared to alternatives like bubble wrap, foam cushions emerge as a superior choice in terms of durability, reusability, and impact resistance. If you are a shipper of products that require consistent protection and presentation, foam cushions offer a dependable solution that ensures your packages reach their destination unscathed.

Get started today with Fastpak for your packaging and shipping needs.